Executive Summary

The global electrification of aviation, transportation, and industrial systems is creating urgent demand for electric machines that combine high power density, operational safety, and supply‑chain resilience. Conventional permanent‑magnet machines rely on rare‑earth materials, driving cost volatility and limiting fault tolerance. At the same time, existing brushless field‑excitation approaches struggle to meet the demands of high‑speed, lightweight applications. Researchers at Michigan State University have developed a breakthrough optically powered synchronous machine platform that eliminates rare‑earth magnets while enabling compact, brushless, high‑speed operation. By delivering rotor field excitation through optical power transfer (OPT) rather than mechanical brushes or inductive/capacitive systems, this technology achieves high specific power density, inherent electrical isolation, and simplified system architecture. Simulation and experimental results demonstrate performance that meets or exceeds state‑of‑the‑art permanent‑magnet machines in power density, speed capability, efficiency, and safety—while offering unparalleled control over rotor flux and system fault response.

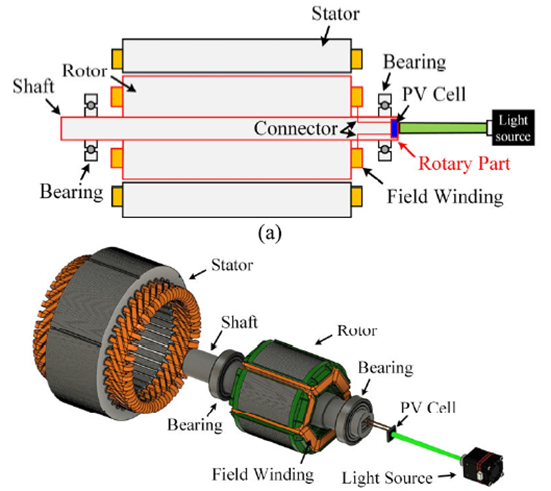

Description of the Technology

This technology is based on a brushless wound‑field synchronous machine in which rotor field excitation is supplied through an optical power transfer system. A stationary light source delivers power to a photovoltaic (PV) cell mounted directly on the rotor shaft, which converts optical energy into DC excitation for the field winding. Compared with inductive or capacitive wireless power transfer systems, the optical approach:

- Eliminates heavy passive components and rotating rectifiers

- Avoids electromagnetic interference (EMI)

- Maintains efficiency and reliability at very high rotational speeds

Because the optical link is inherently electrically isolated, it also enables seamless integration of rotor position and speed sensing with minimal added mass or complexity. Comprehensive analytical modeling, finite‑element analysis, and experimental validation show that optically excited machines can deliver:

- Competitive or superior power density

- High‑speed operation unconstrained by brush wear or onboard power electronics

- Fail‑safe operation, including rapid field de‑energization during faults

A proof‑of‑concept prototype has already demonstrated stable optical excitation at low speed. Larger, higher‑speed, and higher‑power variants for aerospace and industrial platforms are currently under development.

Benefits

- High specific power density, even at elevated rotational speeds

- No rare‑earth magnets, reducing cost, supply‑chain risk, and environmental impact

- Brushless excitation without rotating electronics, improving lifetime and reliability

- Switchable rotor flux, enabling enhanced safety, fault tolerance, and control

- Inherent electrical isolation, supporting high‑voltage and safety‑critical applications

- Scalable architecture, applicable from kilowatt‑class systems to tens of kilowatts and beyond

Applications

- Electric and hybrid‑electric aircraft (generation and propulsion)

- Advanced air mobility (AAM) and UAV platforms

- High‑speed power generation (turbomachinery‑coupled generators)

- High‑performance robotics and industrial drives

- Electrified mobility systems requiring lightweight, safe, and controllable machines

Patent Status

Published application WO2025170637A2

Licensing Rights

Full licensing rights available

Publications

"Brushless Wound Field Synchronous Generator Design With an Optical Power Transfer", IEEE Trans. Magn., Sept. 2025.

"Torque Harmonics Mitigation in Wound Field Synchronous Generators With Asymmetric Rotors for More Electric Aircraft," IEEE/AIAA Transportation Electrification Conference and Electric Aircraft Technologies Symposium (ITEC+EATS), Anaheim, 2025.

"Analysis and Design of Brushless Wound Field Synchronous Generator with Optical Power Transfer for High Speed Applications," IEEE Energy Conversion Conference Congress and Exposition (ECCE), Philadelphia, 2025

Inventors

Dr. Woongkul (Matt) Lee, Dr. Kangbeen Lee