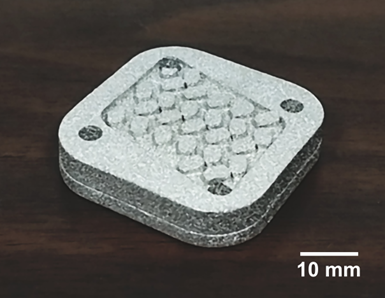

FABRICATED GREEN HEAT EXCHANGER PLATES BY SEAM PROCESS SINTERED STACKED HEAT EXCHANGER ASSEMBLY

Executive Summary

Metal additive manufacturing is an attractive process for producing highly complex and tailored components from superalloys for high temperature applications. However, the processes can be slow and are not scaleable for large volume production. Researchers at Michigan State University have recently developed an efficient additive manufacturing process for metal parts that is scalable, low cost and creates parts with very high relative densities with no geometrical distortion. The process can be also used to make complex structures with enclosed channels.

Description of the Technology

The technology is based on an additive manufacturing process using UV light curing of mixture composed of a photopolymer and metal powders termed SEAM (scalable and expeditious additive manufacturing). Layers of powder suspension are cured with digital UV light projection over in a layer by layer process followed by debinding and sintering to create a dense part. The process also includes a two step partial curing process and may include co-debinding and co-sintering of multiple parts. Experiments have been conducted using stainless steel, copper and aluminum. The technology has also been demonstrated with a Haynes 214, Nickel based superalloy to manufacture parts for a high temperature super critical CO2 heat exchanger (photo above).

Benefits

- Allows large building platform

- High speed of manufacturing, lowers costs

- High part density achieved up to 99.5% relative density with no geometrical distortion

- Superior surface roughness compared to laser sintered process

- Micron level accuracy

- Scalable manufacturing process allows multiple parts to be formed at the same time

- Allows production of parts with enclosed channels and complex internal structure

Applications

- Parts for high temperature applications including engine turbine blades, nuclear reactors, turbochargers, heat exchangers

- Automotive parts

- Aerospace parts

- Medical / Dental parts and devices

- End of arm tooling

- Jewelry

Patent Status

Licensing Rights

Full licensing rights available

References

“From Photopolymerization of Metal Suspension to Practical and Economical Additive Manufacturing of Haynes 214 Alloy for High Temperature Application”, International Additive Manufacturing Conference IAM2022, 10/19/22

"Photopolymerization of Stainless Steel 420 Metal Suspension: Printing System and Process Development of Additive Manufacturing Technology toward High-Volume Production", Journal of Manufacturing and Materials Processing, 2024

"Dispersant-Induced Enhancement of Rheological Properties in Metal–Photopolymer Mixtures for 3D Printing", Journal of Manufacturing and Materials Processing, 2025

"Development of an innovative, high speed, large-scaled, and affordable metal additive manufacturing process", CIRP Annals - Manufacturing Technology, 2020

Inventors

Dr. Haseung Chung, Dr. Patrick Kwon

TECH ID

TEC2019-0104, TEC2023-0017