Ceramic Micro-Burner

Case ID:

TEC2016-0085

Web Published:

6/9/2025

Ceramic Micro-Burner

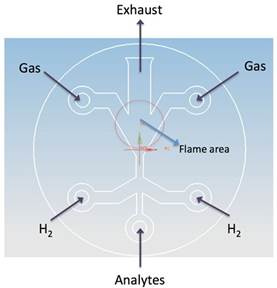

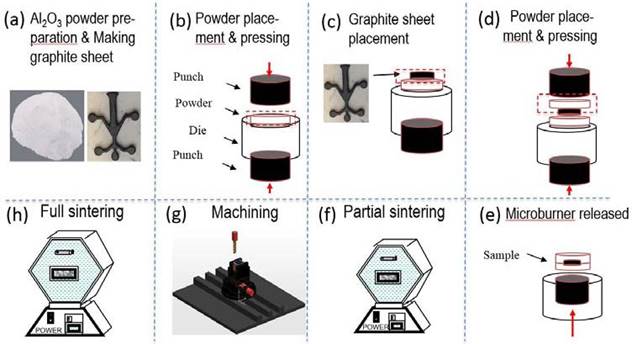

Figure 1: Design of micro-burner Figure 2: Sequence of fabrication process

Executive Summary

Microchemical systems (µCSs) are compact chemical and biological process units offering enhanced mixing, excellent heat transfer, and enabling highly exothermic reactions with high yield and specificity. Unfortunately, current materials for making µCSs - such as polymers, glass, silicon and metals – are often constrained by limitations in operational temperature, pressure and chemical resistance due to material degradation. Researchers at Michigan State University have recently developed an innovative fabrication process for ceramic micro-burners that overcomes these limitations. This new method of manufacturing is not only faster and more cost effective but also produces ceramic micro-burners with higher channel accuracy/smoothness compared to conventional ceramic processes.

Description of the Technology

The technology utilizes a process that embeds powered metal oxides with a fugitive phase of graphite. The powered material is compressed into a puck and partially sintered, causing the graphite to vaporize and create empty channels. The puck can be machined and drilled to form connecting holes, after which it undergoes complete sintering to achieve its full ceramic properties. The resulting micro-burner has been tested by burning an oxygen/hydrogen mixture, demonstrating reliable performance over long times and under cyclic operation.

Benefits

- Powder use allows easy flow and confirmation to complex channels

- High temperature, pressure and corrosion resistant materials

- Higher channel accuracy/smoothness and reduced manufacturing time over conventional ceramic process

- No toxic gases formed during the ceramic processes

- Near full density ceramic structures

Applications

- Micro-burners

- Flame ionization detector

- Fuel and biomass reforming

- Chemical sensors

Patent Status

Licensing Rights

Full licensing rights available

References

“Fabrication of Power-based Ceramic Micro-Burners”, Procedia Manufacturing, 2016

‘Fully-Enclosed Ceramic Micro-burners Using Fugitive Phase and Powder-based Processing", Nature Scientific Reports, 2016

Inventors

Dr. Patrick Kwon, Dr. Junghoon Yeom

TECH ID

TEC2016-0085

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |

For Information, Contact:

Jon Debling

Technology Manager

Michigan State University

deblingj@msu.edu